-

Hot

-

Hot859,00 DKK Incl. VAT

THE BATIK PROCESS

THE BATIK PROCESS

Not many people understand and appreciate the workmanship and art form that batik is. Batik is a process of using melted wax as a resist on fabric. The wax may be painted on a white or coloured fabric using a canting or brush or it may be stamped onto the fabric using a copper stamp dipped in melted wax.

The fabric is then dyed, and the areas that have been waxed will not be penetrable by the dye. The process can be repeated many times to get a multicoloured result. Please note that any irregularities or residual wax in the garments portrays the uniqueness of this handmade product.

We have compiled a series of photos from the batik production process for you to follow the process and many steps involved in the production of your garment. The maximum length of fabric that the batik maker can work with is 8-10 meters. This is because certain steps in the process requires the stretching out of the fabric on a wooden frame like a painting. The maximum working length of such a frame is 10 meters.

|

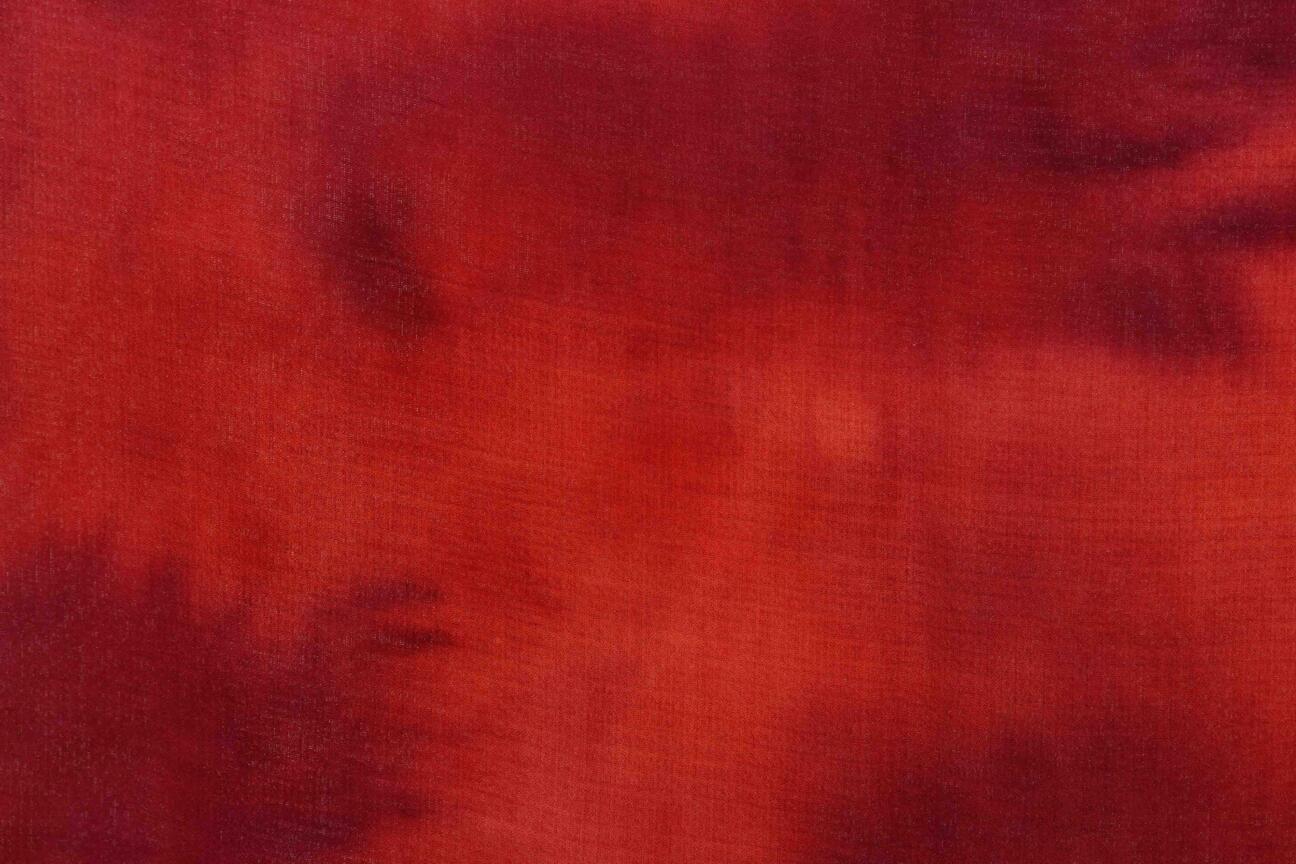

1. This photo shows the white fabric which has been dyed for the first time. This color will be the colour of the stamp or motif of the batik. |

|

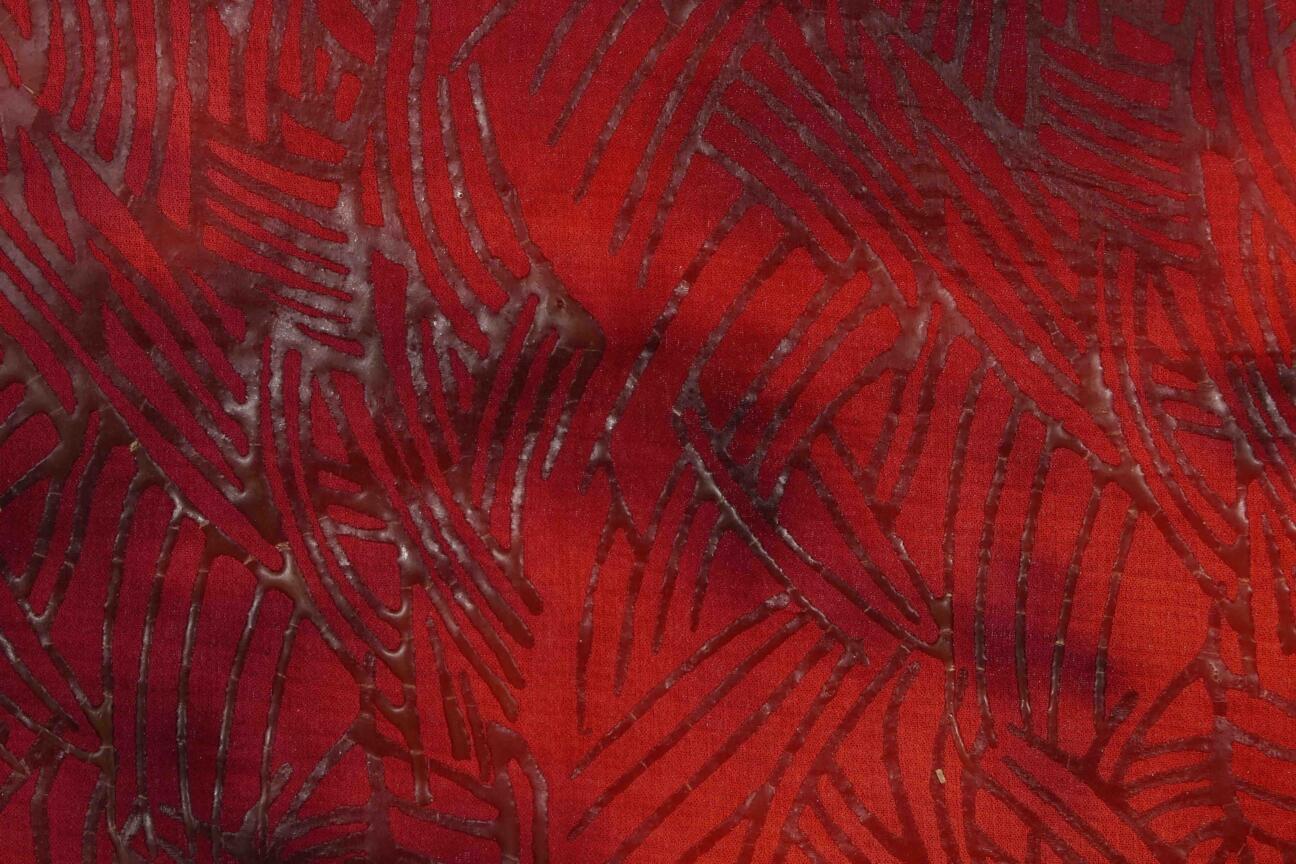

2. The dyed fabric has been hand stamped with hot wax in a design. |

|

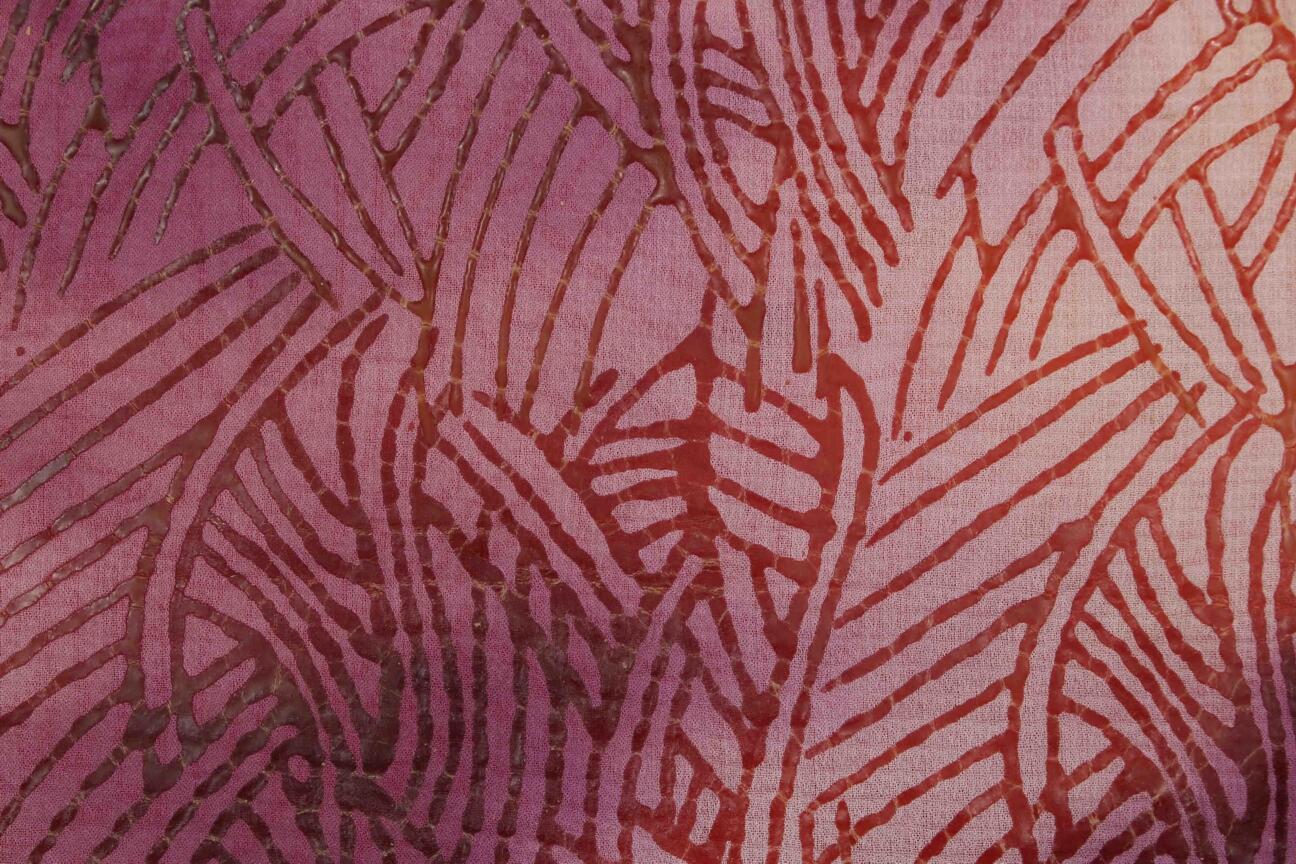

3. The stamped fabric has been bleached, so the background fabric which is without wax has lost some of its color. |

|

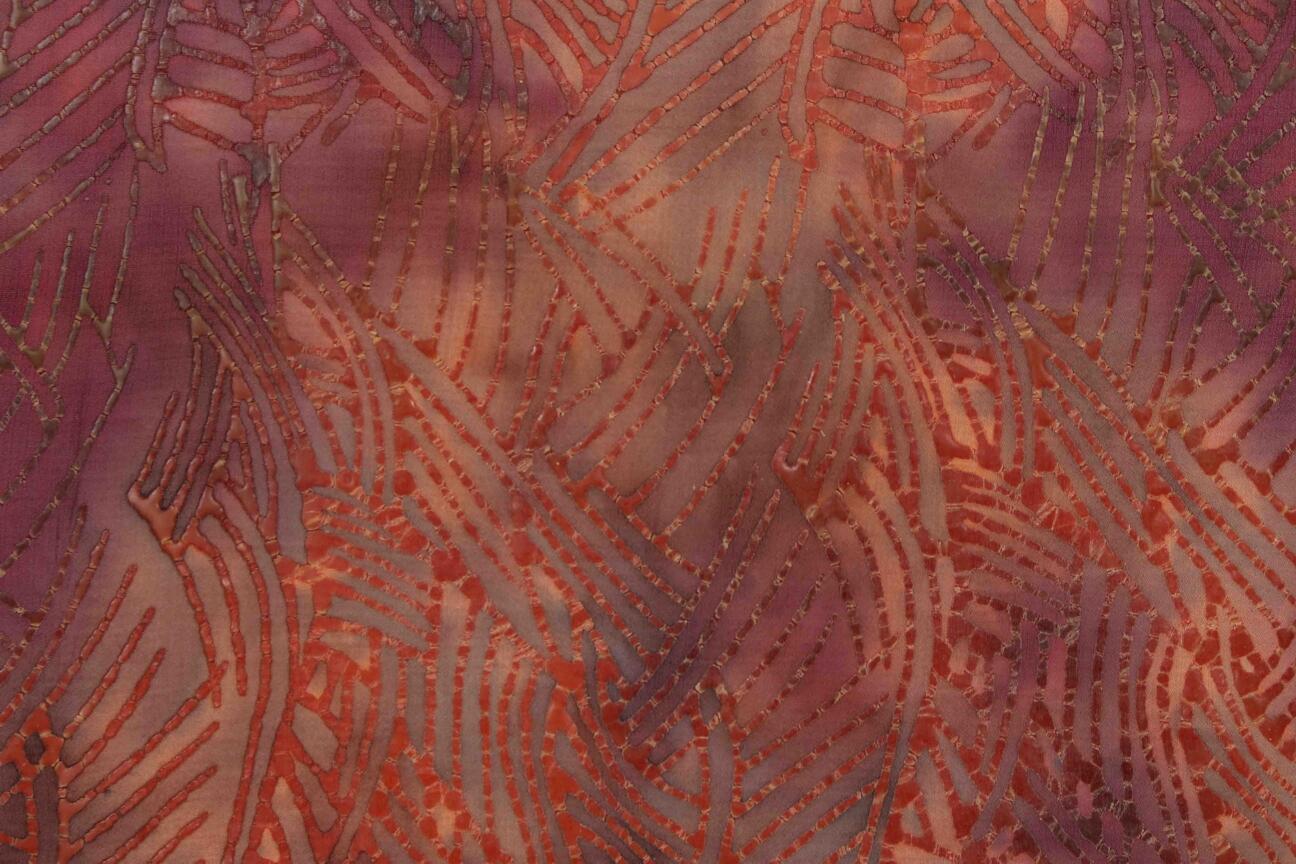

4. The bleached fabric has been re-dyed. I tis only the fabric without wax that is able to soak the dyes. |

|

5. The fabric is "smoked" to get a more nuanced background colour. |

|

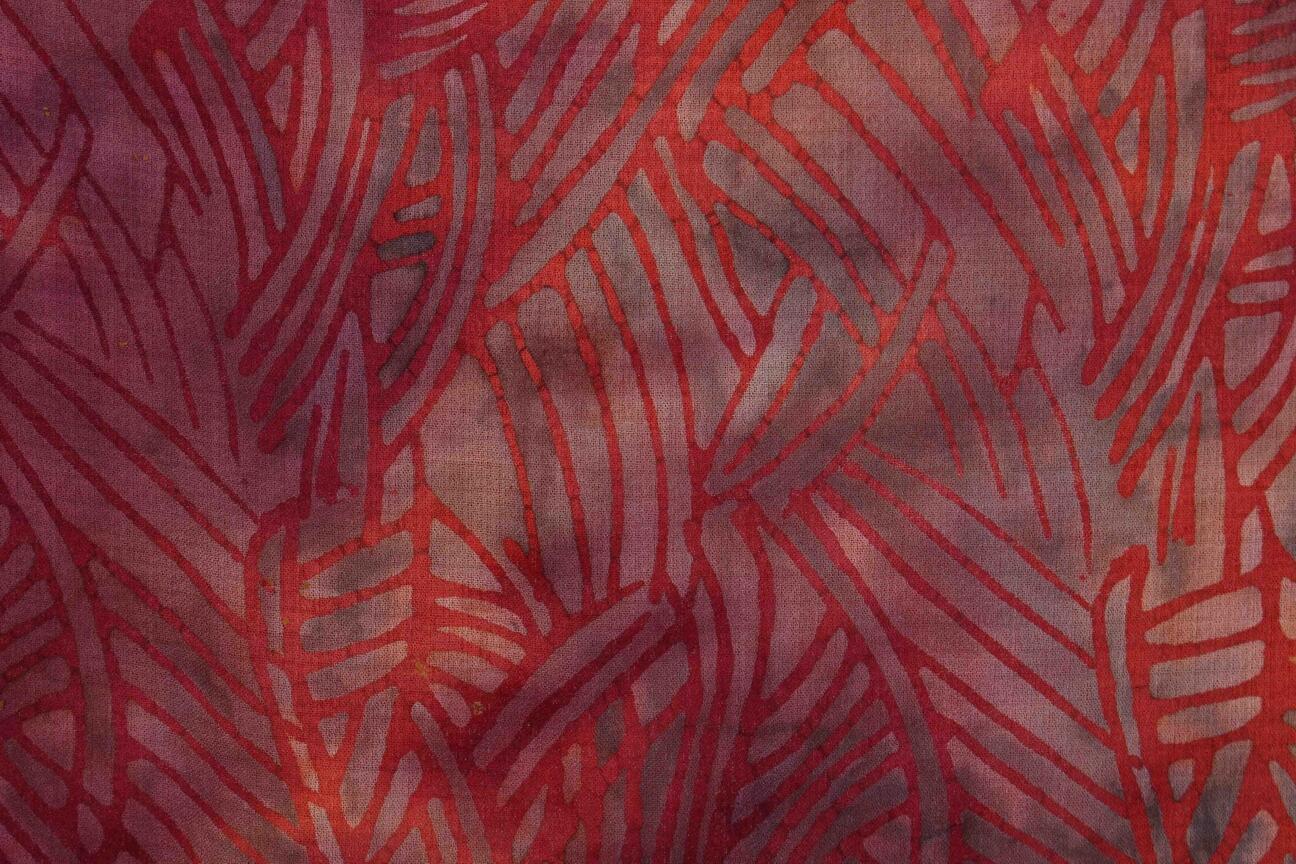

6. The final result after the fabric has been boiled to remove the wax. The design made by the wax stamp is prominent as it has a stronger red color that the redyed background color. |

Traditionally cottons and silks were batiked using natural dyes in indigo blues, soga browns and black. Today with the development of artificial dyes we are gifted with all the colours of the rainbow. In our production we have always only used German developed ISO 100 certified dyestuffs from Dyestar for all our dyeing.

With the development of contemporary batik, the variety of designs and techniques available for the batik maker has increased. There are a multitude of different techniques that you can apply to tweak the outcome or look of your batik. This is the real magic of the batik maker to continue to make batik interesting with new effects and techniques that live up to modern day fancies.